PRODUCT ENQUIRY

Cogeneration Systems – Combined Heat & Power

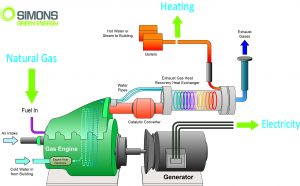

Cogeneration, also known as Combined Heat and Power (CHP), is the simultaneous production of two forms of energy – electricity and heat – from a single fuel source. Cogeneration uses a natural gas-powered engine to generate electricity on site and converts the waste heat from the engine into usable heat for space heating, process heat for manufacturing, domestic hot water, heating for swimming pools and similar applications.

On site Cogeneration Systems have a total efficiency of up to 85%, as compared to the 30% efficiency of coal-fired grid-supplied electricity.

Simons Green Energy, as part of the Simons group of companies, is a leading provider of sustainable energy, heating and cooling solutions in Australia.

For more information about Cogeneration & Trigeneration please go to www.simonsgreenenergy.com.au

Cogeneration Explained

Mingara Recreation Club Saves $350,000 A Year With Cogeneration

Trigeneration Explained

Project @ Canterbury Hurlstone Park RSL Club

Castle Hill RSL Green Club & Trigeneration Project

For more information about

Cogeneration & Trigeneration please go to:

simonsgreenenergy.com.au Features & Benefits

Cogeneration systems use natural gas or biogas powered engines to produe electricity on site. Ideally for high energy users with constant demands for electricity and heat, Cogeneration can reduce energy costs and carbon emissions by up to 50%.

Biogas is derived from the natural breakdown of organic matter and utilising it as a fuel has a double environmental benefit – it is a carbon neutral fuel providing the same advantages as mains gas fired CHP, and it saves the release of the methane gas to the atmosphere where it is potentially more harmful to the environment.

Benefits

- Improves energy efficiency

- Produces sustainable energy

- Reduces electricity costs

- Cuts carbon emissions

- Provides “”free”” heating

- Delivers energy savings for over 20 years

Paralleling Diesel Generators

Paralleling Diesel Generators

The Problem

In the past few years, we have seen a major shift in the way electricity retailers charge for your electricity usage. This shift results in exorbitant peak demand charges, while lowering consumption rates on a kilowatt-hours (kWh) basis. Peak demand charges now make up a large proportion of the total bill for commercial and industrial customers.

If an electrical peak is hit at one point, this will be seen as a high KVA charge over the next year. Very often, these peak demands are infrequent, and only occur during very hot periods, where the majority of the power is being directed to air conditioning systems, which, in turn, struggles under the hot temperatures and high load.

The Solution

One solution to the above problem is to use existing diesel backup generators that may already be onsite as an auxiliary source of power, and to use this power in conjunction with the grid only during these high demand periods.

By modifying the backup generators control system, and modifying the control system for the Automatic Transfer Switch (ATS), the backup generator is able to automatically start up at times of high demand, and limit the demand reached. This will effectively limit the peak electrical demand that a site requires from the grid and also the high KVA expense that a site experiences.

This system will burn extra diesel in the engine, but this cost will be vastly outweighed by the reduction in expense, and the systems are designed to operate less than 500hours per year. Modifications typically have a 1.5 – 3 year payback period for appropriate clients.

It is, of course, much more complex than it sounds, and because every generator set is different, systems must be tailored for individual sites, generators and switchboards. Also grid approvals are required.

Simons Green Energy and our partners, Lakewood Electrical, would be happy to review your existing generator system, and prepare a feasibility study in order to develop a solution for your premises.

Please get in touch with us on 02 8338 8660 to discuss converting your backup generator to an automatic paralleling peak lopping generator.

Related Products

Related PROJECTS

In the News ...

PRODUCT ENQUIRY

Cogeneration systems

Applications

- Clubs, aquatic and leisure centres

- Hotels

- Food and beverage manufacturers

- Commercial and residential buildings

- Hospitals

- Abattoirs and rendering plants

- Industrial facilities

- Universities

- Airports

- Government buildings

- Airports

- Landfill sites

- Chemical and pharmaceutical manufactures