Simons Green Energy recently completed a “Technology Demonstration Site” in Frankston, Victoria which compared three different Micro-CHP technologies.

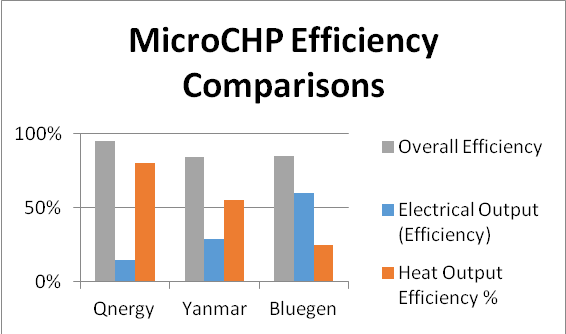

| Qnergy | Yanmar | Bluegen | |

| Technology | Stirling Engine | Lean Burn Reciprocating Engine | Fuel Cell |

| Overall Efficiency | 95% | 84% | 85% |

| Electrical Output (Efficiency) | 15% | 29% | 60% |

| Heat Output Efficiency % | 80% | 55% | 25% |

| Use | High hot water requirement, grid-purchase electrical reduction. Boiler replacement with a payback. | Sites with balanced electrical and heat loads. | High efficiency onsite electricity generation. Low-carbon replacement for grid-sourced electricity. |

Micro combined heat and power or micro-CHP is an extension of the idea of Cogeneration. Micro-CHP can be used in small scale Cogeneration applications, such as residential developments, care facilities, leisure centres, restaurants, supermarkets and hotels or large homes.

Simons Green Energy recently completed a “Technology Demonstration Site” in Frankston, Victoria which compared three different Micro-CHP technologies.

|

Yanmar – Yanmar’s internal combustion CHP system uses a lean burn miller cycle reciprocating engine with waste heat recovery to heat hot water. Yanmar engines can burn natural gas or biogas. |

|

Qnergy – Qnergy can use a range of fuel sources to power a combustion Stirling engine, creating electricity. The waste heat is captured and used to heat the hot water supply. Qnergy has a very long service life and is a low maintenance generator. |

|

Bluegen – Bluegen is a micro fuel technology CHP unit. As natural gas passes over the fuel cell, a chemical reaction creates electricity and heat at a very high electrical efficiency |

A COMPARISON OF TECHNOLOGIES |

|||

| Qnergy | Yanmar | Bluegen | |

| Technology | Stirling Engine | Lean Burn Reciprocating Engine | Fuel Cell |

| Country of Origin | Israel/USA | Japan | Australia/Germany |

| Overall Efficiency | 95% | 84% | 85% |

| Electrical Output | 6.5 | 5 | 1.5 |

| Electrical Output (Efficiency) | 15% | 29% | 60% |

| Heat Output kW | 36 | 9.7 | 0.6 |

| Heat Output Efficiency % | 80% | 55% | 25% |

| Use | High hot water requirement, grid-purchase electrical reduction.Boiler replacement with a payback | Sites with balanced electrical and heat loads. | High efficiency onsite electricity generation. Low-carbon replacement for grid-sourced electricity. |

| Electrical / Heat Split | Very high heat generation efficiency, low electrical generation efficiency | Middle of both | Highest electrical conversion efficiency available, low heat output |

| Fuel Capability | Natural Gas/Propane/Biogas | Natural Gas/Propane | Natural Gas |

| Technical Notes | Sealed maintenance free generator so very low running costs. Designed for long life >60,000 hours. External combustion engine, so with correct burner configuration and setup, can be run on various gaseous fuels including biogas and landfill gas with impurity tolerance. | Proven reciprocating engine technology. Long, 10,000 hour service intervals. | Advanced fuel cell technology provides the highest efficiency local electricity generation possible. |

| Examples of applications | Aquatic Centres. Commercial space heating. Industrial or Agricultural biogas applications. | Large Households with pools, small hotels and aquatic centres | Household |

Simons Green Energy also installed a trigeneration system at The Frankston Arts Precinct, which is a landmark theatre and art gallery that welcomes over 200,000 visitors per year.

The 120kW trigeneration system is providing electricity to the building as well as heating and cooling to the building. This system will help reduce Frankston Art Centre’s energy expenditure, and help the City of Frankston move towards its 2025 carbon neutral target.

VIEW FRANKSTON ARTS CENTRE PROJECT DETAILS